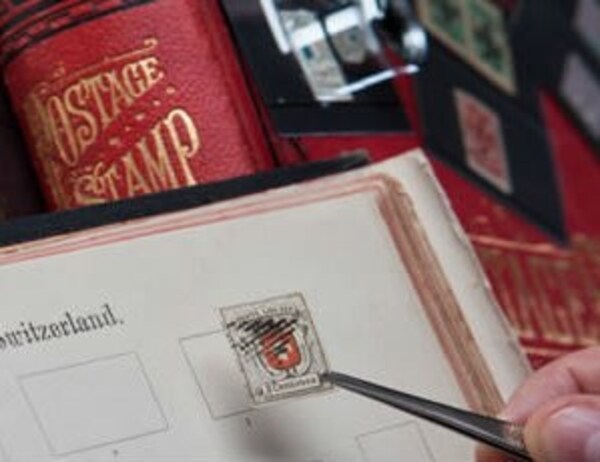

Aside from collecting regularly issued stamps many collectors are keen to enhance and expand their collections with errors and varieties, either from the printing or perforating process.

From the first appearance of Postage Stamps in 1840 until about 1850, all stamps were issued imperforate i.e. they were individual images printed onto a sheet of paper and had to be cut into individual values, pairs, strips or blocks with scissors or a knife and rule. This was an extremely time-consuming and error-prone process, especially with sheets of closely printed stamps and in some countries postal clerks were required to avoid “defacing” the Monarchs portrait.

In 1847, Henry Archer constructed the first rouletting machine, to separate stamps. Two such machines were built. After experimentation both machines proved to be failures. From one machine a few 1d red stamps from Plates 70 and 71 have survived. This machine consisted of lancet-shaped blades working on a fly-press principle and piercing the paper with a series of cuts.

Archer then abandoned this approach in favour of perforation, a process which used rows of small round pins to punch out the holes. In 1848 Archer patented his “Perforation Machine” which worked on the "stroke" principle. The arrangement of the pins enabled the top and sides of each stamp across the row to be perforated in a single operation, and this became known as "comb" perforation. New machines based on Archer's principles were constructed by David Napier and Son Ltd; these were initially used in October 1853 for Great Britain revenue stamps and from January 1854 for postage stamps.

The standard for describing perforation is the number of holes in a 2-centimetre span. The finest gauge ever used is “Perf 18” on stamps of Singapore in the early 1950s, and the coarsest is “Perf 2”, seen on the 1891 stamps of Bhopal.

Stamps that are perforated on one pair of opposite sides and imperforate on the other have most often been produced in coils instead of sheets, but they can sometimes come from booklet panes. Booklet panes can be associated with any combination of one, two or three imperforate sides. Sheet edges can produce any one imperforate side or two adjacent imperforate sides when the stamp comes from the corner of the sheet.

As is inevitable with any mechanical process like perforating, many things can go wrong. “Blind perfs” are common; occurring when a hole is not completely punched out because of damage to the perforating pin, similarly an entire row of damaged pins can produce “Imperf between” errors running the length or breadth of the entire sheet. Although it is very common to have different gauges of perforation horizontally and vertically, “Compound perfs,” in rare circumstances a stamp may have different perforations on opposite sides. Again with mechanical wear the hole size can vary giving “Irregular perfs”.

Most of these errors are the result of mechanical failure or lack of maintenance, however there are many instances of man-made varieties either inadvertent for example a sheet being mis- fed and the perforator missing a row or fed in upside down, but there are also very popular confections such as the so called “Palace mis-perfs” of Egypt, created to fund King Farouk’s spending habits.

In our Sandafayre Sale of the 10th May (Sale 5253) you will find a superb range of these perforation errors including a very rare vertical pair of Costa Rica 1875 ½r blue “Imperf between” plus a substantial range of South Africa varieties including a 1925 9d airmail “Imperf to left margin” and even a rare “Imperf” 36p Alderney Womble!

General

General

General

General

General

General